e-F@ctory was launched in 2003 to help companies solve various issues.

As per Mitsubishi electric, the e-F@ctory concept is an initiative for extracting hidden benefits from existing resources through integrated automation. The ultimate aim is to improve efficiencies, reduce costs, and increase overall productivity.

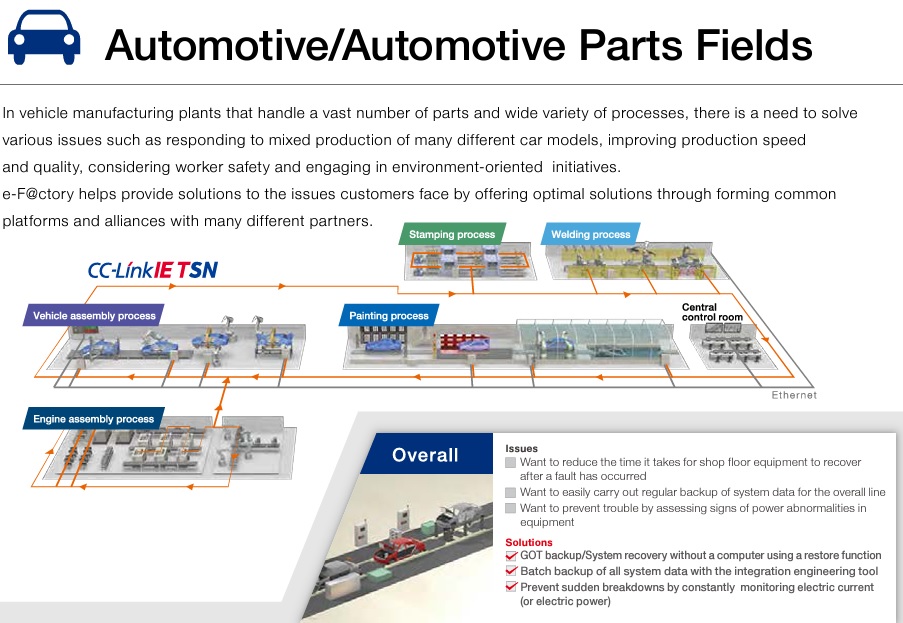

It is one of the world’s leading industrial automation suppliers, Mitsubishi Electric partners with other companies with an open platform provided with technologies to enable partner’s products in a seamless way to integrate with theirs.

The partnership formed is known as the e-F@ctory Alliance. It is a union of technology experts. The “e-F@ctory” is developed with an FA-IT integration solution. The core of such advanced technologies is “edge computing” which utilizes AI for collecting data from the production shop floor and analyzing it in real-time.

The e-F@ctory targets the “one-stop” operation with IoT proposals for the shop floor and realizing the digital shift.

Why should you go for an e-F@ctory solution?

- Smart factories are created by leveraging advanced digital technologies to achieve digital transformation in the manufacturing environment for enhanced operational efficiency.

- Seamless integration is enabled in plant operations with Business Management Systems for Better Shop-floor visibility.

- The data can be collected, analyzed, and diagnosed to improve the better quality of manufacturing in real-time.

- It is the Next Generation Solution to reduce the computing burden with compact AI and enable the deployment of AI for higher productivity.

- It promoted an “Open” Shift to accelerate collaboration and innovation in manufacturing for greater sustainability.

Why Mitsubishi electric?

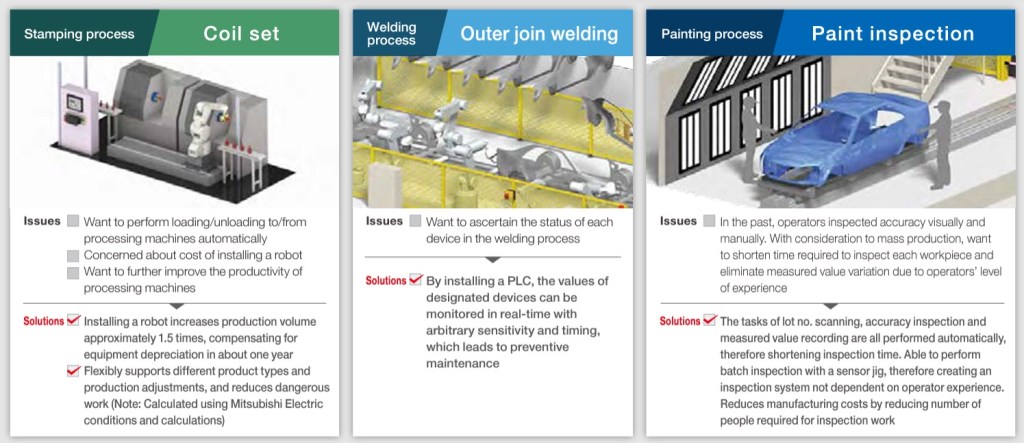

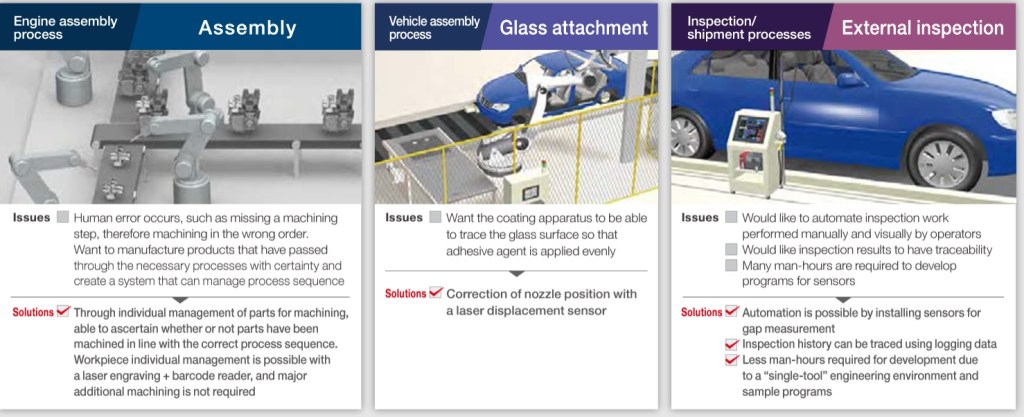

It is among the top automation suppliers globally. It has revolutionized products for more than 90 years. The complete automation portfolio includes PLCs, drives, CNCs, motion control, HMIs, energy monitoring, and management, industrial robots, and connectivity for MES and ERP applications bringing higher productivity and quality to industrial applications.

As per Mitsubishi electric, the smart factory key is edge computing. It is essential to utilize the real-time production shop floor data and efficient connectivity with IT systems.

They propose IoT solutions to suit the customer’s goals covering everything from collecting shop floor data to analysis and diagnosis and even connectivity to IT systems and clouds.

Let’s check the video at an event held @Mumbai, AutomationExpo 2022,