The company name means Hi-Tech winner. They are also focused on the “prevention of pollution, the reduction of waste material, the saving of resources and energy, and the protection for employees’ health & safety.”

HIWIN Technology Corp. was established in October 1989. The founder of the company, Cho Yung-tsai. The global headquarter is Taichung, Taiwan. The company revenue recorded in 2018, was 47.02 Crores USD.

It is a Taiwanese company involved in manufacturing machinery components.

The overseas subsidiaries are in Germany, the USA, Japan, Switzerland, the Czech Republic, Singapore R&D Centers, Tokyo (Japan), Offenburg (Germany), Moscow (Russia), and Yiselie.

HIWIN Technologies holds the largest manufacturing market in precision linear-motion devices such as ball screws, linear guideways, and industrial robots. The products are involved in sectors such as precision machine tools, optoelectronics, medical, solar energy, semiconductor, environmental protection, energy-saving, industrial machinery, and biotech.

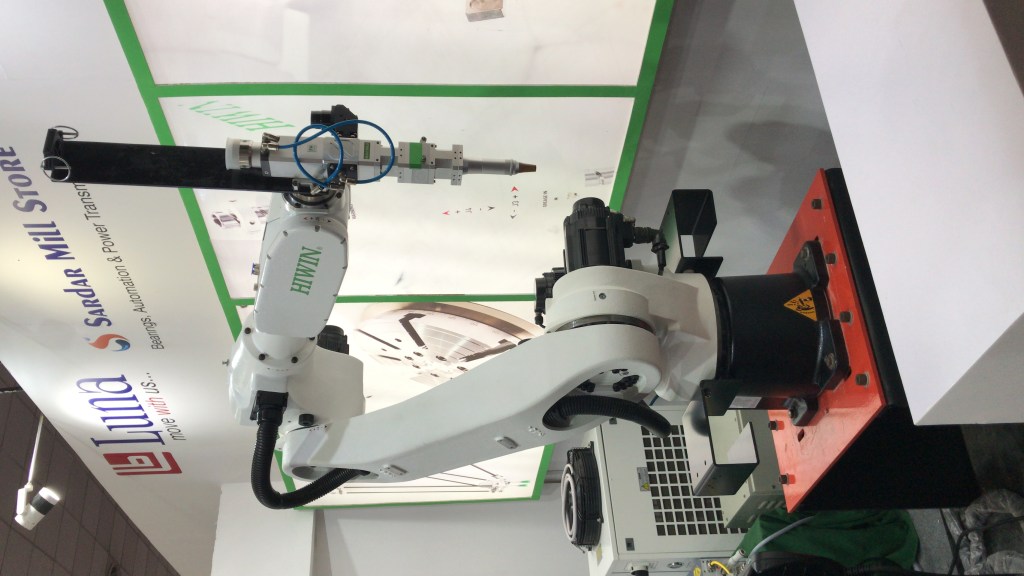

HIWIN robots include Gripper, Articulate robot, SCARA robot, and Delta Robot. Six rotary axes with absolute encoders is included in HIWIN robots. It is allowed for unlimited orientations and points combinations while 20µm repeatability is maintained.

HIWIN Single-Axis Robot Total Solution

- A diverse range of fully integrated linear stages with HIWIN single-axis robot to configure with other motors or automated mechanisms.

- HIWIN Single Axis Robot and Servo Motor and Drive. It allows the integration of both mechanical and electronic parts for reducing the assembly time of the customer.

- KK/SK single-Axis-Robots- It is a dustproof module with high precision ballscrew drive for optimal u-shaped rail to provide high precision and rigidity.

HIWIN Multi-Axis Robot

- Articulated Robot- RA/RT Series

It is a compact and agile 6-axis joint arm robot for precise assembly, part transfer, and workpiece loading/unloading. The applications include pick and place, handling, assembly, deburring, grinding, and polishing.

- SCARA Robot-RS series

It is an excellent solution for rapid motion in the horizontal plane for pick and place and assembly. The applications are in the plastic, automobile, electronic, pharmaceutical, and food industries.

- Delta Robot-RD Series

It is a 4-axis parallel robot utilizing the parallel linkage mechanism for performing extremely high-speed motions with stability and high accuracy. The application includes pick-and-place, assembly, alignment, and packaging.

- Wafer Robot-RW Series

It uses high precision and stiffness DD motor for repeatability to reach ± 0.02mm. It includes small circling radial and high utilization of the space. It is useful in the vertical integration of both hardware and software. The applications are Pick-and-place equipment in the semiconductor industry, Optoelectronics (mini panel, mini solar panel), and the LED industry (sapphire substrate, rubber ring).

The drives can be used in the Automation industry, processing machines, turning and winding machines.

Check out the live demo of their products at an event held in Pragati Maidan, Delhi,

Let’s check the video at an event held in Mumbai, Automation Expo,