An exclusive interview with Dr. Charusmita, Director at Statcon Energiaa. Her focus is on discovering innovative ways of bringing knowledge of high-power electronics into common parlance.

Statcon Energiaa, specialized in sophisticated development of power converters and solutions. The company cater products to various sectors, including solar energy, hydrogen production, defence, and industrial applications.

Statcon Energiaa also received an award for innovation at the REI for micro-grid inverter products in 2022.

Read here for Part 1.

Q: How does Statcon Energiaa support renewable energy systems and their contribution to India’s sustainable development?

Dr. Charusmita:

We are supporting the nation’s objectives for sustainable energy in a number of ways. Earlier, we went into Solar in the years 2011 and 2012. Our major focus was on power supply solutions.

But as soon as solar power came into effect and started becoming big in India, we realized that whatever we are designing, manufacturing, and supplying has to be in line with the country’s vision for its sustainable development. So that is when we shifted our focus to renewable energy.

Now, how do we do that?

We currently cater to five divisions: solar, power, defense, railways, and green hydrogen. So, very clearly, solar and green hydrogen are renewable energy sectors.

In green hydrogen, we make the power supplies that energize the electrolyzer, converting renewable energy into usable, reliable electricity. The renewable connection in this area of work is direct.

In solar, we make solar containers, solar inverters, and other kinds of solar solutions. So it is clear enough that whatever we are producing goes into direct renewable energy generation.

But for other sectors, such as railways and defense, power supply solutions are not essentially inherently renewable energy products, but we are making those products in a way that can be integrated with different kinds of renewable energy.

For example, in railways, we make integrated power supply systems used in safety systems and, basically, signaling and telecom in railways.

So we are integrating it with solar so that the power can have solar as a backup and as their battery charging. So the product is inherently not made for renewable energy generation, but we try to integrate whatever power-intensive equipment we are manufacturing.

They should be enabled to be integrated with renewable energy. So in the future, if they want to integrate their existing machines with solar, wind, biomass, or hydrogen, they can do that.

We are also working on research and development for defense products, which would help harness renewable energy in remote areas. So, they have different kinds of power supply solutions for these remote army areas or forward areas.

So we are making it integral to that.

We make industrial battery chargers. Not all of our products are currently enabled for renewable integration, but we aim to primarily make all of our products in such a manner that they can be integrated in some form or another with renewable energy.

Q: Tell us something about Extended producer responsibility.

Dr. Charusmita:

This is basically for manufacturers in India. This is the Extended Producer Responsibility Act, which came out in 2022. And it is for waste management.

It requires large companies to adopt and implement policies for proper management of different kinds of waste. So in our case, it would be electronic waste and metallic waste.

We also have an EPR certificate and, under that we are registered. We are approved for that. So we send that waste into recycling and even in the manufacturing process.

Q: Another aspect of Statcon Energiaa contributes to India’s sustainable development.

Dr. Charusmita:

The third aspect to which we are contributing is how we are making the manufacturing process itself sustainable.

How are we doing that?

Both our headquarters office as well as our huge manufacturing facility—the factory alone is one lakh twenty-five thousand square feet. Both of these facilities are powered by solar power.

Even the manufacturing itself, the electricity, the energy that goes into our manufacturing, into lighting, our R&D, our toilets, our rooms, our labs, our work floors, everything. That is all powered by a hybrid solar inverter, which again is manufactured by us.

We are trying to use our technology to make our manufacturing process sustainable!

In terms of contributing to the nation’s sustainable development program, we are doing it on three levels.

The first level is the products that we are manufacturing and the technology that we have—designing and manufacturing—that is how we are trying to make everything renewable.

Second, whatever waste or scrap we produce, we minimize it by sending the relevant items for recycling.

The third is how we are trying to make our manufacturing process sustainable by powering all of our facilities with solar power.

Q: Can you tell me about the obstacle that you faced while switching over completely to a hybrid, solar power? So how did you cope?

Dr. Charusmita:

Hybrid solar technology has still not evolved in India. We installed it back in 2014/2015.

At that time, the challenge was that we were still using DG sets because some of the products and some of the machinery were required to be working without any interruption, i.e., 24/7.

Handling the change and the kind of space needed to make it expandable was a crucial task for us. The biggest challenge was determining the correct capacity of solar technology needed for the plant. We switched to a bigger capacity of solar technology for our renewable energy plant from our smaller solar technology due to the expansion of our plant.

The expandability and scalability of renewable integration became a challenge that needed to be overcome.

We installed a huge BESS solar container solution in our factory to cater to the new demands due to increased production and the scale of the company. The new solar container solution that was installed now caters to the whole factory.

“As we need to evolve with the technology, what better way than to install it in our facility, and address those challenges.”

Q: Please explain Solar containers, Solar Inverter Solutions, and any other major products.

Dr. Charusmita:

We make all kinds of solar inverters. Our company excels in customizable solar solutions.

Solar Container Solutions

What usually happens is, that companies have big containers inside which the inverters and batteries container are included.

In our case, all the power electronics are integrated into the container. So the encasing is not the encasing of the inverter, which is placed inside the container. It is the container itself. It is a modular solution, a solar container solution, and we have supplied it to major microgrids and other solar companies. Also, mobile office spaces and elective places where there is no grid connection.

We provide these extremely specific container solutions, something that many other businesses do not. Thus, one of our areas of expertise in solar is this.

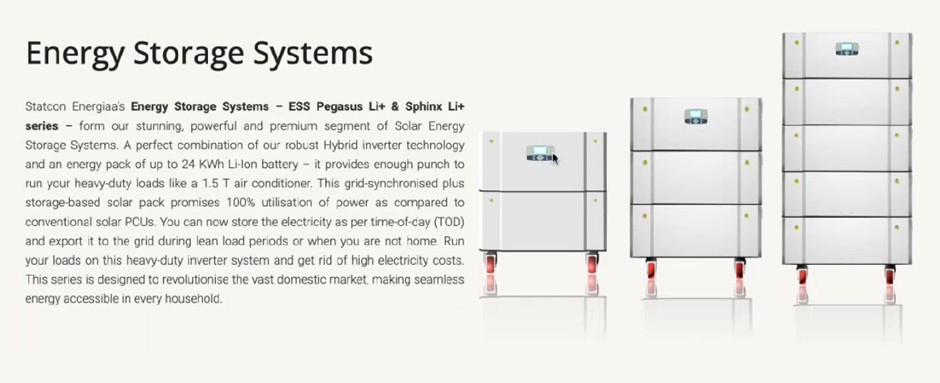

Energy Storage Solutions

The top drawer and the top rack in all of these contain the inverter inside. And the other drawers have batteries.

We made these energy storage systems will have the inverter as well as the battery. If in future you want to increase the storage, you can increase one one drawer. So these won’t take up much of your horizontal space.

This makes it future-proof.

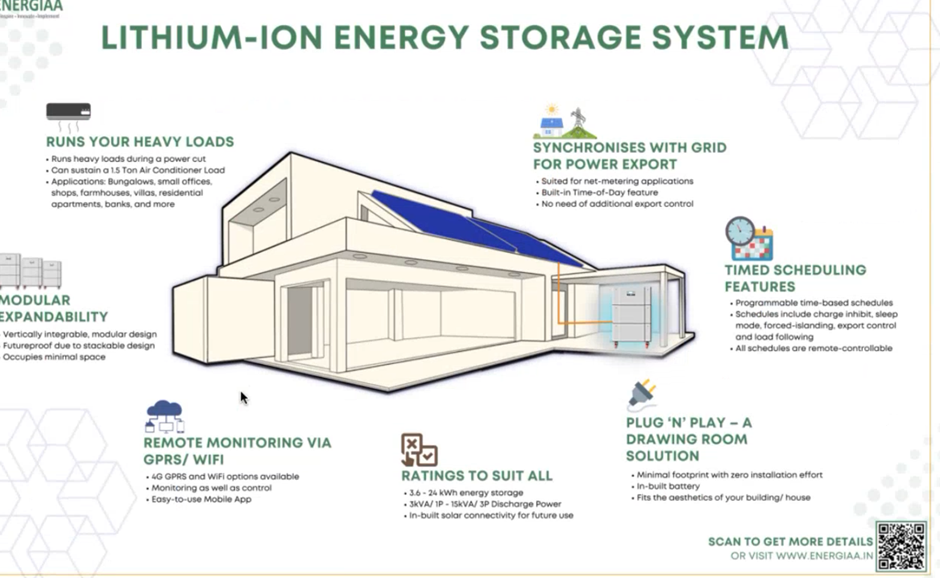

One of our very, very popular products, is lithium-ion energy storage systems. It runs air conditioners. Nowadays, everyone expects even when you enter a mall, the air conditioner is working, even if there’s a power cut.

So, these huge systems cater to big loads, such as running ACs in offices, homes, and big malls.

Solar on-grid inverter

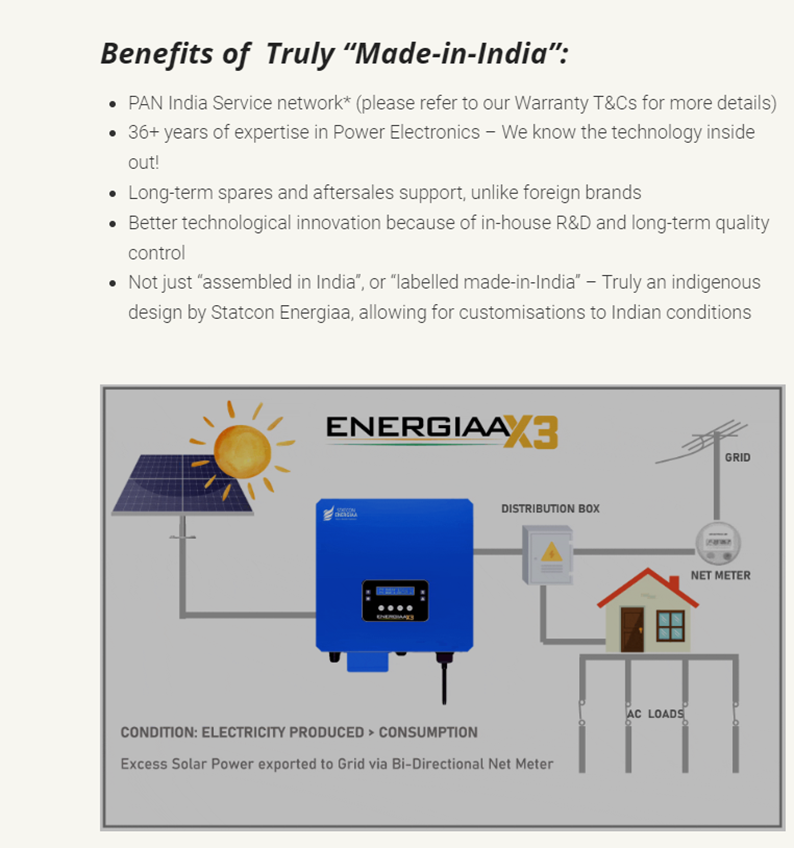

One of the most established technologies on the market. The importance of this product is that we just launched a small on-grid solar inverter of three kilowatts. The beauty of our product is that it is truly “Made in India.”.

Every solar company in India is offering or even manufacturing on-grid solar inverters; the design is either not theirs or they are just assembling it in India.

This is the first time that the coding, the software, the technology—everything—is Indian and made by Statcon Energia.

We are now going to start our campaign, where we are going to be inviting journalists and people from different industries to come and see us because our distributor initially did not trust us. They said, “No, really? You must be just assembling this. It’s not possible.”.

Even huge brands get their original equipment manufactured in China or other countries and then just put their label on the white label marketing, and then they sell it in India.

Or the companies that say that, yes, it is made in India, the technology is, and the technology and the components come from outside, and they assemble it.

Q: And what about the cost?

Dr. Charusmita:

We say specifically about this product, it is equivalent to Chinese pricing. Probably lesser, but that is not due to lack of a global quality. It is equivalent to the best on-grid brand in the global market.

And the spare support and the after-sales of the customers must be considered by whoever is using or thinking of venturing into adopting solar.

This product will be beneficial for them because they will never have to scrounge to find spare parts.

After all, it’s being shipped from another country, or they don’t have to wait around for the person to come and diagnose their issue, and then, you know, the spare parts are not available and they’re coming after two months; it’s not going to happen with them.

So the customers are not going to suffer. We have a brand new product for them, with very competitive pricing and an attractive blue-looking color, which would probably look great on their roofs and in their homes. So we are hoping that it will be widely popular.